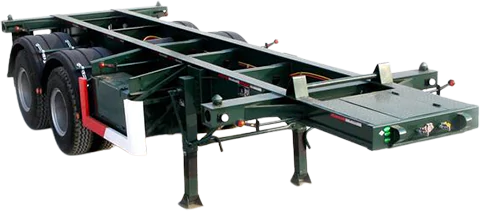

Buy shipping containers for as low as $1,350.00! CALL US TODAY! (888) 977-9085

Rent shipping containers for as low as $95.00 a month. CALL US TODAY! (888) 977-9085

Rent-To-Own Shipping containers for as low as $79.99 a month. CALL US TODAY! (888) 977-9085