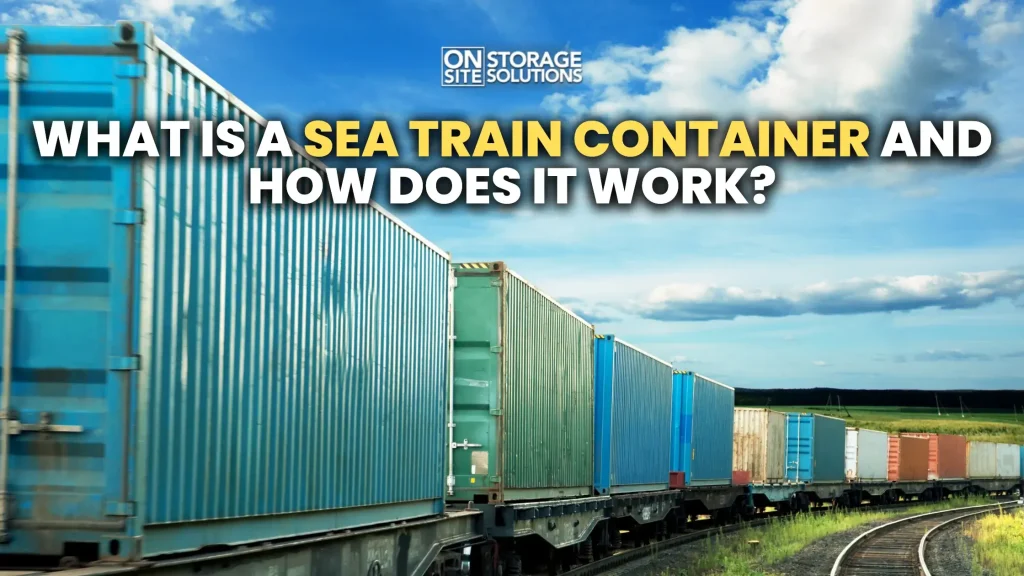

A Sea Train container represents one of the earliest breakthroughs in integrated freight transport, where rail and sea joined forces to move cargo more efficiently.

These containers not only made logistics more practical during their time, but they also laid the foundation for how global trade functions today.

Let’s explore what Sea Train containers were, how they operated, and why their legacy still influences modern shipping.

The Origins of Sea Train Containers

Back in the late 1920s, the Sea Train Shipping Company introduced a radical concept.

They envisioned a way to avoid the expensive, labor-intensive process of unloading railcars at the docks just to reload cargo onto ships.

Instead of handling cargo multiple times, why not ship the entire railcar?

From that simple idea, the Sea Train system was born.

The company’s name, “Sea Train,” described the operation perfectly: trains that traveled the seas.

These containers were used to carry freight between ports while remaining inside custom-designed railcars.

It eliminated the need to unpack and repack, simplifying the workflow and reducing time, labor, and overall costs.

It was the beginning of something much bigger than anyone could have imagined.

Understanding the Sea Train Container

A Sea Train container was a specialized steel cargo unit built for durability and ease of transfer between rail and sea transport.

Unlike today’s ISO containers, Sea Train units were not standardized in size or design.

Each container was built for specific types of cargo and transport configurations.

They were designed to be hoisted by crane, loaded directly onto ships, and then transported by rail, without opening the container or disturbing the goods inside.

These containers were the prototype of seamless logistics.

Although bulky compared to modern cargo containers, their durability and reusability made them a smart investment for shippers.

They significantly reduced the handling process, which was a game-changer in early freight operations.

How the Sea Train Container Operates

So, how did the Sea Train system work in a real-world scenario?

Products were directly loaded into the Sea Train container at the manufacturing plant or storage facility.

That container was then transported by rail to the port, usually while still secured inside a railcar.

At the dock, cranes lifted the railcars or containers onto a specially designed cargo ship.

During the voyage, the containers remained sealed.

Once they arrived at the destination port, the process reversed.

The containers were lifted off the ship, placed back onto railcars, and sent to their final destination.

This method removed many of the inefficiencies of break-bulk shipping and inspired today’s intermodal freight containers.

The Evolution: From Sea Train to Modern Shipping Containers

Sea Train containers were the conceptual predecessor to modern intermodal units.

Today’s containers follow international ISO standards, the 20-foot and 40-foot standard shipping containers are built for stacking, and are easily transferable between ship, rail, and truck.

While Sea Train units were customized and often heavier, the operational logic remains the same.

One container, multiple modes of transportation, minimal handling.

Visionaries like Malcolm McLean later perfected the system, standardizing containers and revolutionizing the shipping industry.

But Sea Train laid the groundwork.

Without their early innovations, we might not have the efficient global logistics we rely on today.

Impact of Sea Train Containers on Freight Logistics

The Sea Train container is a historical milestone in the world of containerized shipping solutions.

Its biggest contribution was eliminating the repeated loading and unloading of goods between different transportation modes.

This efficiency improved cargo container shipping security, reduced labor costs, and sped up delivery times.

These benefits still define modern shipping today.

Sea Train’s system was also the precursor to today’s global trade networks.

It created the foundation for logistics that are fast, flexible, and far-reaching.

Without Sea Train containers, the concept of same-container transport from the factory floor to overseas markets might not exist.

Do Sea Train Containers Still Exist?

The original Sea Train containers have been out of service for many years.

They’ve been replaced by lighter, standardized shipping containers used in modern logistics.

However, their influence lives on.

Some vintage containers from that era survive as collectors’ items or are repurposed for creative use, as tiny homes, storage sheds, or mobile offices.

For today’s businesses and individuals in need of robust, wind and water-tight storage containers, On-Site Storage Solutions provides modern alternatives.

These containers embody the same principles: portability, protection, and performance.

Conclusion: Why the Sea Train Container Still Matters

The Sea Train container wasn’t just a piece of equipment, it was a logistics philosophy ahead of its time.

Its goal was to revolutionize freight transport by making it more efficient, quicker, and seamlessly integrated.

And it succeeded.

While the equipment itself has evolved, the strategy it inspired continues to power the engines of global commerce.

Sea Train’s legacy is built into every shipment moved by container today.

For anyone in shipping, storage, or supply chain management, understanding where we came from helps shape where we’re going.

It reminds us that innovation doesn’t always begin with new technology. It often starts with a smarter approach to old challenges.

By examining historical models like the Sea Train, we uncover timeless logistics principles that still influence how freight flows across continents today.

Reliable Modern ISO Container Solutions

If you’re looking for dependable and secure container solutions in today’s market, On-Site Storage Solutions is your trusted partner for reliable, cost-effective second-hand shipping containers.

As the highest-rated supplier of shipping containers across North America and Canada, we pride ourselves on delivering exceptional service and unmatched quality.

With an A+ rating from the Better Business Bureau, we ensure every container meets the highest standards of durability and security.

Our containers are weather-resistant and secure, making them perfect for a wide range of needs, either for transporting goods, business use, or tiny house projects.

We offer fast delivery from multiple depot locations and flexible rental or rent-to-own options to suit your budget and timeline.

You need a 20-foot container for storage or a 40-foot high cube for export. On-Site Storage Solutions has you covered.

Call us now at (888) 977-9085 to have your container delivered today and experience the best in shipping container solutions.

Your storage solution is just a phone call away.